Staged fuel gas only burners

NATURAL AND FORCED DRAUGHT

The I.C.E. “SF” (Staged fuel gas only burners) burner design started in the late 90’s as an answer to market request of low NOx burners, suitable to meet pollutant emissions regulations.

Coupling practice and feedbacks from site, the target has been a safe and reliable equipment to help site operators avoiding potentially dangerous situations.

Further, burners must have the capacity to follow process variation without losing in performance.

Natural and forced draft versions are available to fit a variety of process applications, where key parameters are:

- High reliability

- Good flame stability

- High turn-down ratio

This burner line is designed focusing on:

- Reliability as first priority

- Safety in operation

- Flexibility and easy to use design

Engineered for a wide range of gaseous fuels thus producing stable flame operation with a broad range of excess air, it also ensures a wide turn-down range (depending on fuel pressure supply).

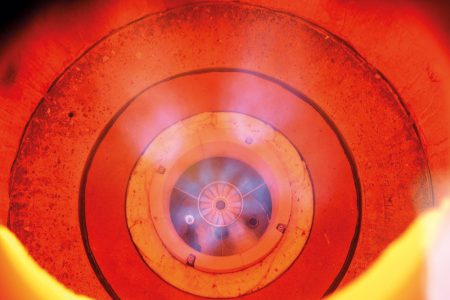

Our staged fuel technology (a special internal design developed to meet the most stringent environmental regulations) allows to reach very low NOx levels, for many operating cases lower than 100 mg/Nm3.

Thanks to our special jacketed refractory design and company’s experience in developing tailor made solutions, the “SF” burners are the right approach to any kind of gas ring process application.