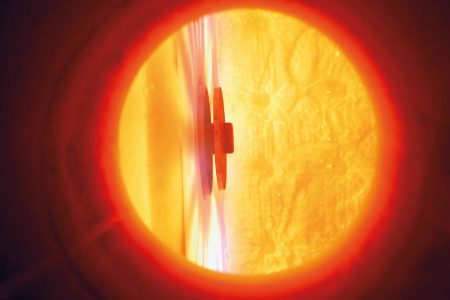

Radiant burners

I.C.E. has added radiant wall design burners starting from early 2000, with a proven track list of successful installations, including some HTAS furnaces, even if not included in their approved supplier list yet. Process of approval has started and we consider this challenge as one of our major target for next year.

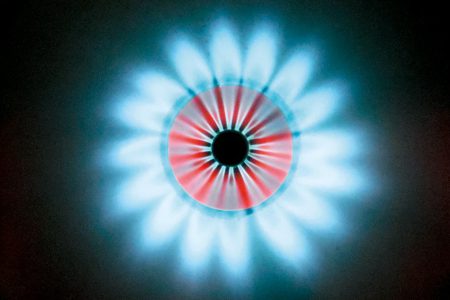

We are capable to design burners with small mechanical impact, developing flower type flame, able to stand any of your applications ranging from EDC / Ethylene crackers to reformers.

Custom designed burners nozzles to prevent flashback at all loads and ensure smooth and stable combustion is available.

Stand alone refractory design with anchors and support saddles for easy heater fit in.

Raw or staged fuel design are available to meet stringent pollutant emission challenges. Recently, we are testing in our rig also liquid fuel radiant burners, which represents a big challenge due to the particularity of such firing conditions for those burners.

Different streams can be fired simultaneously, thanks to our capability of flexible tailor made design.

Big number of pieces is not a problem, we can deal several burners, due to our steelwork partners and our big network of refractory suppliers.

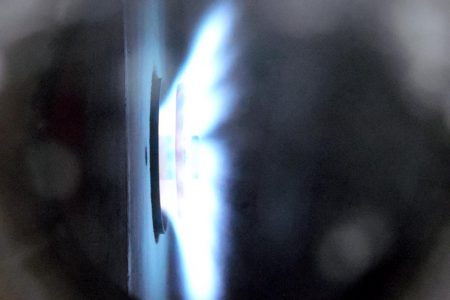

I.C.E. owns two testing facilities with all required ancillaries to ensure successful testing and client satisfaction.